A 24 Volt Sealed Lead Acid Battery Charger (Part 2)

A 24 Volt Sealed Lead Acid Battery Charger (Part 2)

In Part 1, we went over the design of the 24 volt charger. In this Part 2, we will describe the physical build.

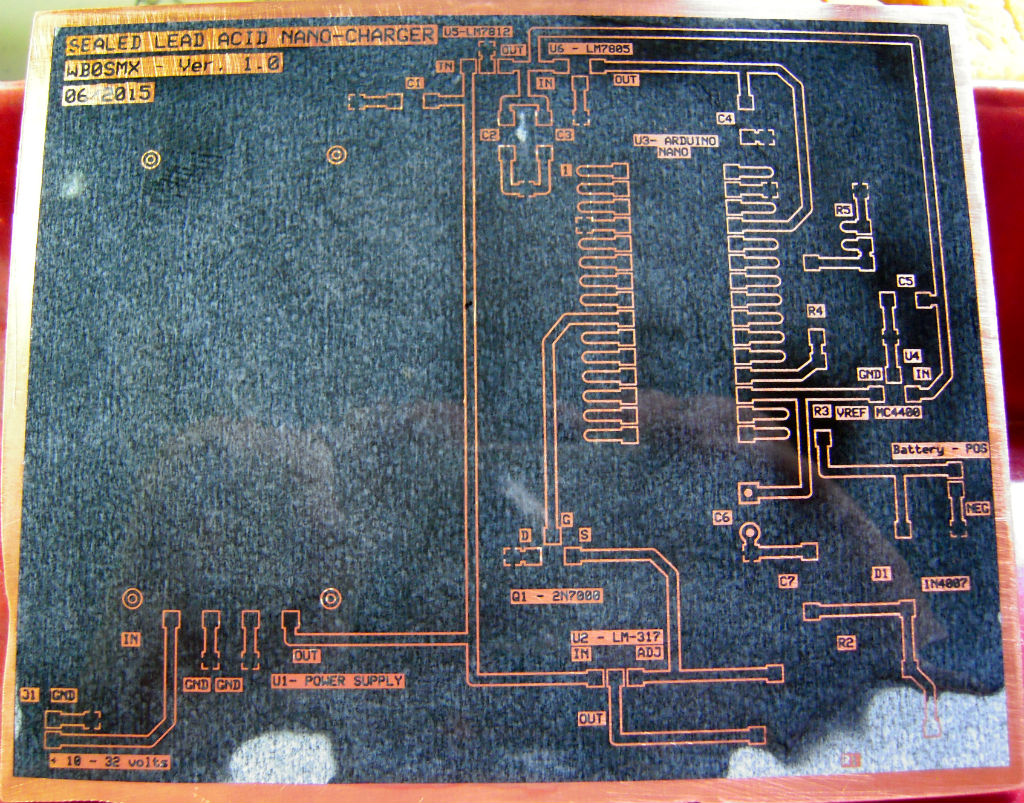

At this point, I developed a PC board to hold all of the components in a solid manner.

Once the board was etched, I marked the holes to mount the Geetech 150 watt boost inverter, shown on the right, below. I followed this with population of the discrete electronic parts on the board. The LM-317, with the big heat sink, is at the top of the picture. The blocking diode that prevents the battery from backfeeding into the circuit is on the left top. The Arduino Nano is mounted on a socket near the middle of the board. Â I made the socket from a couple of 24-pin sockets. One is mounted as a whole unit, and a second, with only 3 pins on each side, is mounted directly below the first, to add up to the 30 pins total needed to accommodate the Nano.

The dropping resistors for the voltage sense circuit is to the left of the Arduino. And finally, the linear voltage regulators are on the bottom of the board (I used a 12 volt regulator to drop down from the 32 volts supplied by the boost inverter, then a 5-volt regulator to further reduce the voltage to Arduino compatible levels).

Once the board was populated and tested, I mounted it in an old Sun SCSI Disk cabinet that I had laying around. The Power to the boost inverter is supplied by the 19-volt brick power supply that was originally for a laptop. It is a 60-watt unit, and is sufficient for our purpose here.

The white and Orange wires are to connect the LED indicators on the front of the cabinet to output leads on the Arduino. The grey lead is to connect to the Anderson Powerpole connectors that feed the battery being charged.

A couple of LEDs were added with 270 ohm current limiting resistors. These indicate Charging (Red) and Resting (Yellow). I used JB-Weld to hold the LEDs and Powerpole connectors in the openings of the disk cabinet.

Here is a link to version 1.2 of the PCB artwork.

I don’t remember exactly why I changed it, as that was 2 years ago. But I believe it was a matter of making parts fit just a little better.Migrated Comments:

July 16th, 2017 at 10:35 am

[…] Part 1 of this project, we covered the general design of the battery charger. Part 2 described the physical construction of the charger. In Part 3, we will cover the calibration and […]

July 16th, 2017 at 10:51 am

Yes, I see the problem. Because of the way browsers save and interpret some characters, the quotation marks near the bottom of the sketch were not saved as normal ascii characters. I was able to fix this after cutting and pasting by re-typing the quotation marks in the sketch (within the arduino IDE), deleting the old marks.

Alternatively, I have edited the original post to include a link to the arduino source code, which may be saved by using a right-click and save-as selection. In both cases, I was able to compile the new code without errors. Good luck, and have fun… Randy WB0SMX

August 11th, 2017 at 6:36 am

Did you publish a source for the PCB artwork other than the photographs accompanying the 3 part article.

August 11th, 2017 at 8:01 am

I have placed links for the PCB artwork at the bottom of this post (Part 2). Ver1.0 is the actual artwork I used for my PCB. As I recall, I found that I needed to adjust the spacing or something on that artwork, and I made a ver1.2 to accommodate those changes. I did not actually etch a new board off of that artwork, as I already had a working charger at that point.

Good luck… Randy WB0SMX

August 11th, 2017 at 11:13 am

I have placed links for the PCB artwork at the bottom of this post (Part 2). Ver1.0 is the actual artwork I used for my PCB. As I recall, I found that I needed to adjust the spacing or something on that artwork, and I made a ver1.2 to accommodate those changes. I did not actually etch a new board off of that artwork, as I already had a working charger at that point.

Good luck… Randy WB0SMX

November 20th, 2017 at 3:40 am

We are looking at building some embedded chargers for remote endpoints (VDSL Modem and some low power gear). I was looking around to fins some inspiration and stumbled on your page. We’d like to go the Arduino route as we can expose a TTY on the modem to monitor it all. I’ had a look at your circuit which covers a lot of what we want to do, then when it came down to doing a PCB I got to thinking that this approache *might* be a little overcomplicated. Obviously the less power components in the high current path the better. So I hunted around for diagrams for the P{SU Module, we use these a lot in other things so I had a few kicking about.

I found this page which goes over these modules in a lot of detail. In particular interest was the diagram here : http://www.360customs.de/wp-content/uploads/2014/05/Schaltung.png.

This lead to therealisation that U2 and U5 could be dropped from your design and you could instead use the information in the information in the circuit to act directly on the PSU AND apply current limiting if desired. A small shunt on battery – would allow you to sample here as per the linked site giving you a full blown smart charger with fewer parts.

I will at this point say I have not tried this yet and it is theory, but its high on my to-do list now.

November 20th, 2017 at 7:53 am

Hi Richard. Yes, there are probably some improvements that could be made to my design. I merely took a decade old design by another ham (AA4PB) and updated it with microprocessor control. I’d be interested in hearing how your experiments work out. Good luck, and 73… Randy